According to the deputy director of the Institute of Mathematics and Information Systems of the Vyatka State University Anton Zemtsov, the development of Russian scientists makes it possible to replace the imported advanced technologies of the industry's monopolists

Scientists from the Vyatka State University have created a complex for automating the production of high-viscosity oil. The use of the complex makes it possible to increase the efficiency of oil production in mines, reduce the negative impact on the environment and the risk of injuries in production, as well as solve the problems of energy saving and import substitution, Anton Zemtsov, deputy director of the Institute of Mathematics and Information Systems of Vyatka State University, told TASS.

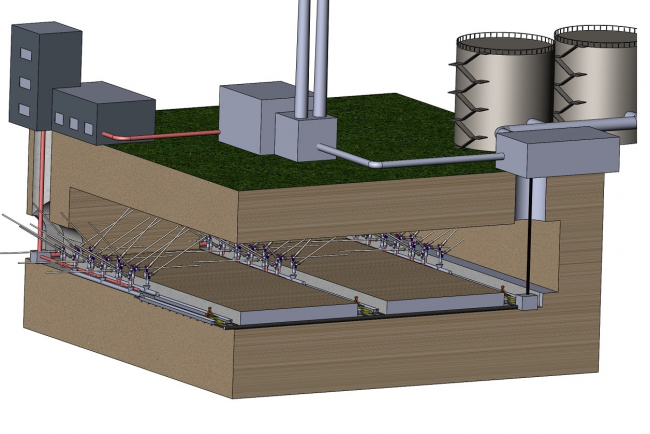

High-viscosity oil is used to produce fuels and lubricants for arctic applications. At the same time, today the technology for extracting such oil is complex and labor-intensive: huge volumes of steam are pumped into the oil-bearing layers from above through the wells, heating and diluting the oil, and at a depth of 150-250 meters in specially created underground galleries, several hundred horizontally inclined wells are drilled, through which heated to 90 degrees and liquefied oil flows down the gallery. The efficiency of oil production in such a complex hydrodynamic system depends on the correct control of hundreds of valves in the wells, while the control is manual, that is, people are forced to work underground in a confined space at high temperatures.

"The Institute of Mathematics and Information Systems of the Vyatka State University has developed a complex for the automation of mine production of hard-to-recover high-viscosity oil. It consists of two parts. The first component is an automated gate valve with a steam separator of its own unique design and a set of sensors, such a gate valve is installed on the well. The second part of the complex is the well cluster control system, which, depending on the measured parameters of each well, balances the operation of the entire valve system" -

Zemtsov said.

He noted that the complex was developed by a team led by engineer of the Institute of Mathematics and Information Systems of Vyatka State University Mikhail Sergeev. The Vyatka State University Engineering Center, which has its own production base, is engaged in the production of components and the assembly of an automated valve.

According to Zemtsov, when using the automation complex, a whole set of tasks is solved.

"There is a possibility of unmanned operation of wells, that is, people do not work with wells in a mine where heated oil is extracted, respectively, the risk of injuries and accidents is reduced. The oil recovery factor increases to 0.75 from 0.51 with the generally accepted development system: the hydrodynamic system of the entire cluster of production and steam injection wells is automatically balanced by the system in order to maximize oil recovery. In addition, a large amount of electricity is saved, since steam is no longer injected into the reservoirs "by eye", its volume is calculated based on data received from sensors of valves in production wells" - said Zemtsov, specifying that today a huge amount of energy is spent on preparing steam and pumping it into the oil reservoir.

Also, automation of mine oil production helps to solve environmental problems, since by optimizing the volume of injected steam, water intake from nearby natural sources is reduced. In addition, according to the interlocutor of the agency, the development of Russian scientists solves the problem of import independence.

"In particular, advanced technologies of industry monopolists - General Electric (USA), Valley Longwall International Pty Ltd (Australia) - are being replaced with imports." - Zemtsov said.

According to him, now the elements of the system are being tested at the oil mines of Lukoil-Komi.

Translation: Artem Sizov